SẢNH LIVE CASINO FEBET

Xóc đĩa Livestream

Tài Xỉu Livestream

Xóc đĩa Livestream

Link Vào Febet Mới Nhất 2025

| – Truy cập FEBET Web PC chính thức: | 👉 https://renttoown.us.org//vi/Browser |

| – Link vào FEBET trên trang web chính | 👉 https://renttoown.us.org//vi/Firefox |

| – Truy cập FEBET qua Viettel | 👉 https://renttoown.us.org/vi/CocCoc |

| – Vào FEBET qua VNPT | 👉 https://renttoown.us.org//vi/Vnpt |

| – Vào FEBET qua mạng FPT | 👉 https://renttoown.us.org//vi/Fpt |

| – Truy cập FEBET qua Mobifone | 👉 https://renttoown.us.org/vi/Mobiphone |

| – Truy cập FEBET qua Chrome | 👉 https://renttoown.us.org//vi/Chrome |

| – Truy cập FEBET qua Safari | 👉 https://renttoown.us.org//vi/Safari |

| – Truy cập FEBET qua Browser | 👉 https://renttoown.us.org//vi/Browser |

| – Truy cập FEBET qua Cốc Cốc | 👉 https://renttoown.us.org/vi/CocCoc |

| – Truy cập FEBET qua Firefox | 👉 https://renttoown.us.org//vi/Firefox |

| – Truy cập FEBET từ ngoài lãnh thổ Việt Nam | 👉 https://renttoown.us.org//Quoc-te |

Febet – Câu Hỏi Hay Gặp

Tổng Hợp Những Đánh Giá Người Chơi

Nội Dung Mới Nhất

-

Cảnh báo truy cập nhầm Febet và Fabet: Bảo vệ tài khoản cá cược trực tuyến

Sự khác biệt giữa thành công và thất bại trong cá cược trực tuyến thường chỉ là một chi tiết…

-

Domain Febet.com: Hướng Dẫn Xác Thực Toàn Diện Cho Người Chơi Việt Nam

Trong suốt một thập kỷ theo dõi ngành cá cược Việt Nam, tôi chưa từng thấy nền tảng nào phát…

-

Phân biệt domain Febet Fabet: Sự khác biệt quan trọng cho người chơi Việt Nam

Tôi đã chứng kiến quá nhiều người chơi mất tiền chỉ vì nhầm lẫn giữa các nền tảng này. Chỉ…

-

Kiểm tra domain Febet: Bảo vệ tài khoản cá cược trực tuyến của bạn

Qua nhiều năm trong làng cá cược Việt Nam, tôi đã chứng kiến quá nhiều người chơi mất tiền chỉ…

-

Febet hệ thống riêng: Tìm hiểu sự khác biệt với Fabet

Với hơn 5 năm kinh nghiệm trong ngành cá cược trực tuyến tại Việt Nam, tôi đã chứng kiến vô…

-

Khác biệt giao diện & bảo mật Febet/Fabet: So Sánh Chi Tiết Cho Người Chơi Việt Nam

Sau nhiều năm trong làng cá cược Việt Nam, tôi đã chứng kiến vô số người chơi bối rối giữa…

-

So sánh Febet và Fabet: Phân tích toàn diện cho người chơi Việt Nam

Sau nhiều năm trong làng cá cược Việt Nam, tôi đã chứng kiến vô số người chơi nhầm lẫn giữa…

-

Nhận biết Febet chính hãng: 5 Cách Đơn Giản Tránh Nhầm Lẫn Với Fabet

Là người làm việc lâu năm trong ngành cá cược trực tuyến, tôi đã chứng kiến quá nhiều người chơi…

-

Febet là gì: Nền tảng cá cược trực tuyến hợp pháp dành cho người Việt

Với hơn 5 năm kinh nghiệm trong lĩnh vực cá cược trực tuyến tại Việt Nam, tôi đã chứng kiến…

-

Febet nhà cái mới: So sánh toàn diện với Fabet cho người chơi Việt

Thị trường cá cược trực tuyến tại Việt Nam đã thay đổi đáng kể trong những năm gần đây. Với…

Nếu bạn đang kiếm tìm một chỗ cá cược thể thao đáng tin cậy và chất lượng cao

Thì nhà cái FEBET chính là sự lựa chọn hoàn hảo cho bạn.

Với tiếng tăm lớn và đẳng cấp khó ai bì kịp, FEBET tự hào đem đến những trải nghiệm cá cược đỉnh cao nhất cho anh em.

Cùng tìm hiểu kỹ hơn về “ông trùm” làng cá cược này qua bài viết dưới đây nha.

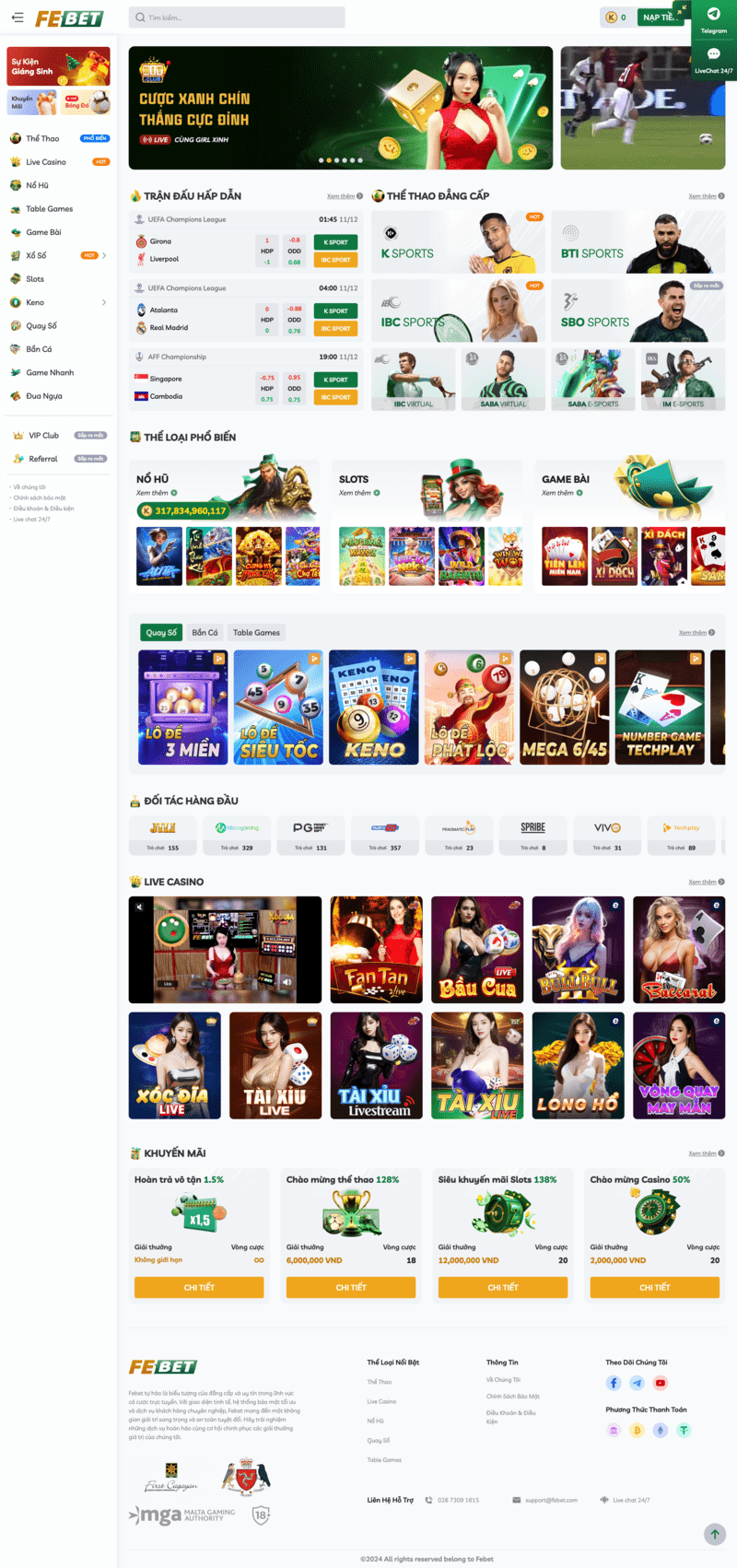

FEBET – Nhà cái cá cược online uy tín số 1 Châu Á

FEBET được cấp phép hoạt động hợp pháp bởi công ty Gaming Curacao ECG có trụ sở tại Curacao.

Kể từ khi ra đời năm 2019, FEBET nhanh chóng nổi lên thành một trong những thương hiệu casino nổi tiếng nhất khu vực Đông Nam Á với hàng loạt sản phẩm chất lượng cao.

Tại thị trường Việt Nam, FEBET chính thức đi vào hoạt động từ tháng 01/2024.

Chỉ trong thời gian ngắn, nhà cái này đã chiếm trọn cảm tình của anh em bởi sự uy tín, minh bạch và chuyên nghiệp trong mọi dịch vụ.

Điểm cộng lớn nhất giúp FEBET khẳng định vị thế của mình là:

- Hệ thống bảo mật tân tiến, đảm bảo an toàn tuyệt đối cho người chơi

- Giao diện web đẹp mắt, thân thiện, dễ sử dụng

- Đội ngũ nhân viên chuyên nghiệp, nhiệt tình hỗ trợ 24/7

Với FEBET, anh em có thể hoàn toàn yên tâm “quẩy” hết mình mà không lo bị lừa đảo hay mất tiền oan.

Kho game FEBET khổng lồ với vô vàn lựa chọn hấp dẫn

Điểm mạnh nhất của FEBET là sở hữu kho game siêu to khổng lồ với hàng trăm tựa game đa dạng, từ thể thao, casino, slot, bắn cá đến xổ số, đá gà… đủ hết.

Nổi bật trong số đó phải kể đến:

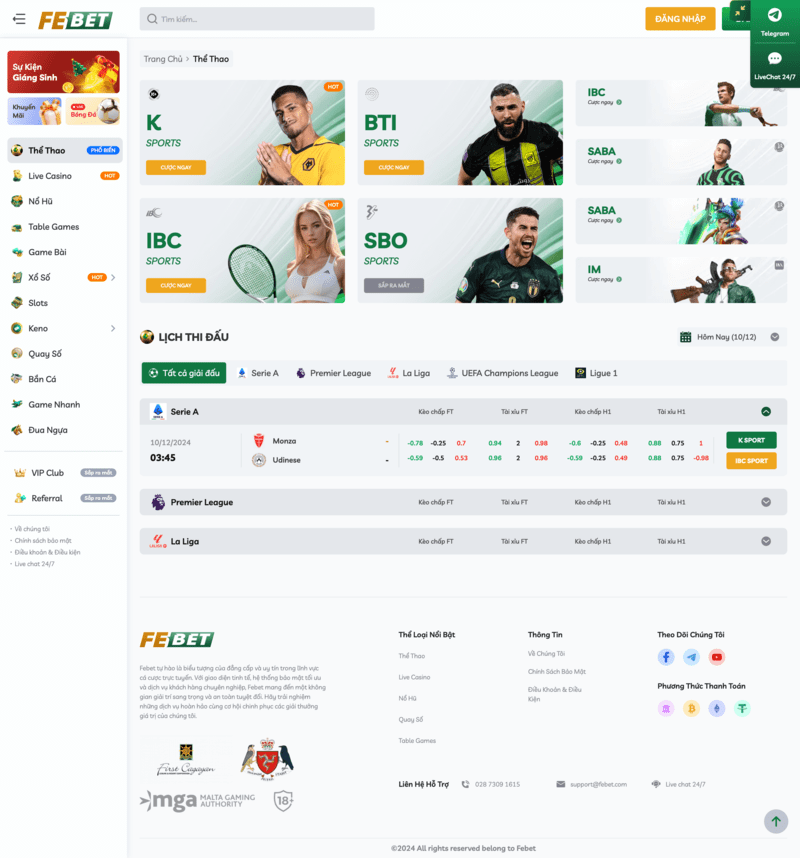

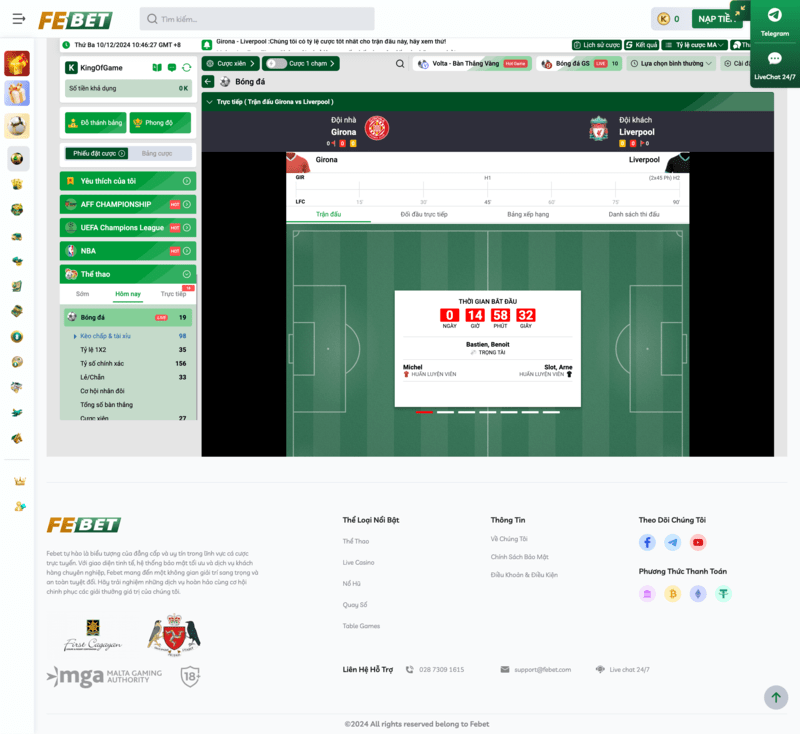

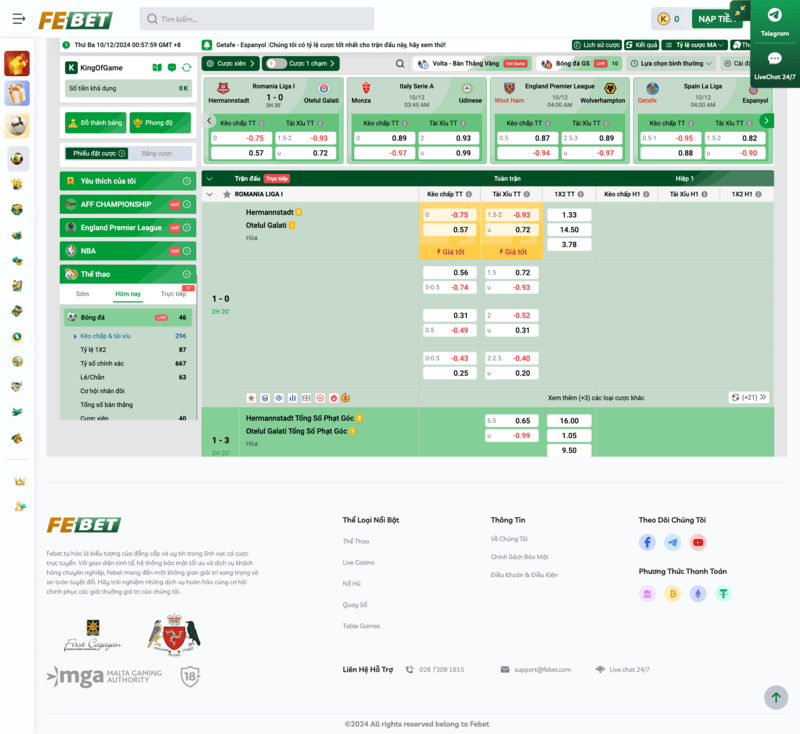

Sảnh cá cược thể thao FEBET

FEBET cung cấp kèo cược phong phú, tỷ lệ ăn cao cho hầu hết các giải đấu thể thao lớn như Ngoại hạng Anh, La Liga, NBA, NFL…

Đặc biệt, anh em còn được xem đặt cược trực tiếp trận đấu, mang lại cảm giác cá cược chân thực nhất.

Sảnh Casino trực tuyến cùng Dealer cực cháy

Sảnh casino tại FEBET cực kỳ sôi động và thu hút với nhiều trò chơi hấp dẫn như Baccarat, Roulette, Blackjack,… cùng dàn MC xinh đẹp.

Anh em sẽ có cảm giác như đang hòa mình vào không gian giải trí VIP tại các sòng bài nổi tiếng trên thế giới.

Sảnh game slot đỉnh cao

Nếu là fan của game slot, anh em không thể bỏ qua kho game khổng lồ tại FEBET.

Hàng trăm tựa game slot với đồ họa sắc nét, hiệu ứng âm thanh sống động và cơ hội trúng jackpot lên đến hàng chục tỷ đồng đang chờ anh em khám phá.

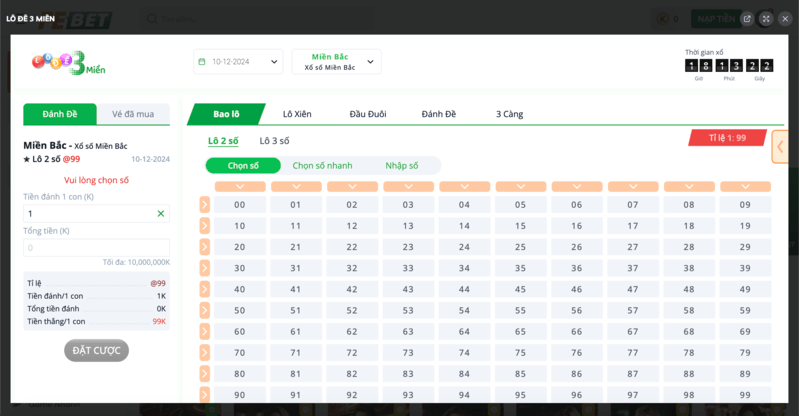

Sảnh xổ số lô đề hấp dẫn

FEBET còn là thiên đường cho anh em mê xổ số lô đề với tỷ lệ ăn cực khủng, lên đến 1 ăn 99.

Ngoài ra, nhà cái còn cung cấp nhiều kiểu chơi khác như keno, lô xiên, đề 3 càng… giúp anh em tha hồ lựa chọn.

Ngoài ra, FEBET còn vô số trò chơi hấp dẫn khác đang chờ anh em khám phá như bắn cá, đá gà, game bài,…

Dù sở thích của anh em là gì, chắc chắn cũng sẽ tìm thấy sân chơi hợp gu tại đây.

Chương trình khuyến mãi FEBET siêu hấp dẫn không thể bỏ lỡ

Không chỉ sở hữu kho game khủng, FEBET còn chiếm trọn tình cảm của anh em nhờ hệ thống khuyến mãi cực kỳ hào phóng. Cụ thể:

- Thưởng 128% lên đến 6 triệu đồng cho lần nạp đầu tiên

- Thưởng 138% lên đến 12 triệu đồng khi nạp lần đầu chơi Slot Game

- Thưởng 50% lên đến 1,5 triệu đồng khi nạp lần đầu chơi Casino

- Thưởng 30% lên đến 2 triệu đồng khi nạp lần đầu chơi lô đề

- Thưởng nạp lại 40% mỗi ngày, lên đến 1,5 triệu đồng

- Thưởng 30% vào mỗi cuối tuần, lên đến 2 triệu đồng

- Thưởng 15% giá trị tiền nạp không giới hạn mỗi ngày

- Tặng 88k miễn phí khi đăng ký tài khoản

Và còn rất nhiều ưu đãi giá trị khác đang chờ anh em rinh về. Với FEBET, cơ hội nhân đôi, nhân ba tài khoản để bet thoải mái là hoàn toàn có thật.

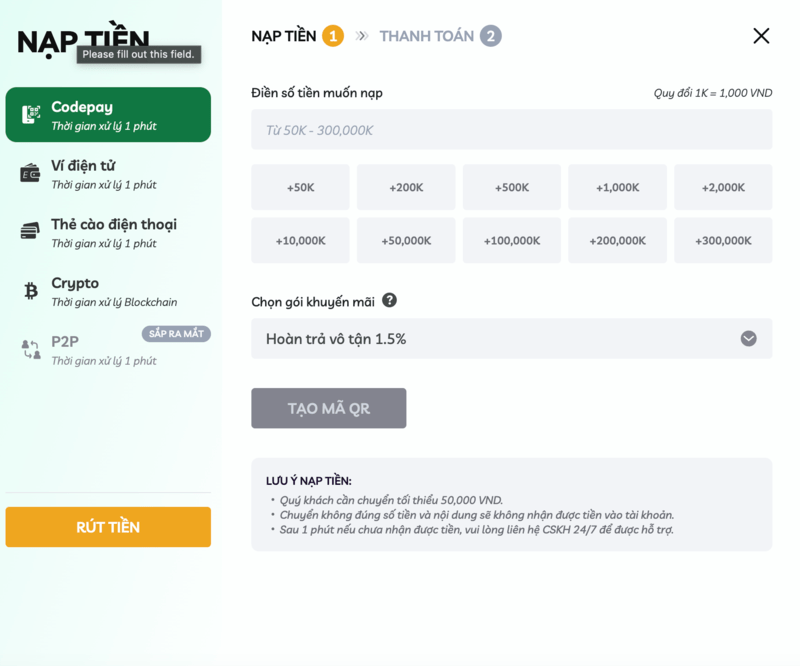

Giao dịch nạp rút tiền FEBET nhanh chóng, bảo mật

Một ưu điểm nữa khiến anh em mến mộ FEBET là hệ thống nạp rút tiền cực kỳ nhanh gọn và an toàn.

Nhà cái hỗ trợ đầy đủ các phương thức giao dịch phổ biến hiện nay như:

- Chuyển khoản ngân hàng

- Ví điện tử như Momo, ZaloPay, ViettelPay

- Thẻ cào điện thoại, thẻ game

- Thẻ tín dụng quốc tế

Chỉ với vài thao tác đơn giản, tiền sẽ được chuyển vào tài khoản của anh em ngay tức thì.

Đặc biệt, mọi thông tin cá nhân và giao dịch đều được mã hóa bảo mật tuyệt đối bằng công nghệ SSL 128 bit và MD5.

Anh em có thể hoàn toàn an tâm khi giao dịch tại FEBET.

Chính sách bảo mật FEBET và chơi có trách nhiệm

Là một nhà cái uy tín, FEBET luôn đề cao tính minh bạch và công bằng trong mọi hoạt động.

Cụ thể, FEBET cam kết:

- Ngăn chặn mọi hình thức gian lận, bảo vệ quyền lợi người chơi

- Thực hiện kiểm tra bảo mật ngẫu nhiên để đảm bảo sự toàn vẹn của hệ thống

- Xử phạt nghiêm khắc các trường hợp vi phạm, gian lận

- Khuyến khích chơi có trách nhiệm, đặt giới hạn tiền cược hợp lý

Với FEBET, anh em có thể yên tâm tận hưởng không gian giải trí lành mạnh, công bằng và an toàn tuyệt đối.

FEBET có dịch vụ chăm sóc khách hàng tận tâm

Một yếu tố quan trọng góp phần tạo nên thương hiệu FEBET là dịch vụ chăm sóc khách hàng vô cùng chu đáo và tận tình.

Với phương châm “khách hàng là thượng đế”, đội ngũ nhân viên FEBET luôn nỗ lực hết mình để đáp ứng mọi nhu cầu của anh em, thể hiện qua:

- Thái độ phục vụ nhiệt tình, chuyên nghiệp

- Hỗ trợ 24/7, kể cả ngày lễ

- Đa dạng kênh liên hệ như hotline, livechat, email

- Xử lý nhanh gọn mọi yêu cầu, khiếu nại

- Lắng nghe và tiếp thu mọi góp ý để cải thiện chất lượng

Với FEBET, anh em sẽ luôn cảm thấy được đồng hành, hỗ trợ và tôn trọng như những vị khách VIP thực thụ.

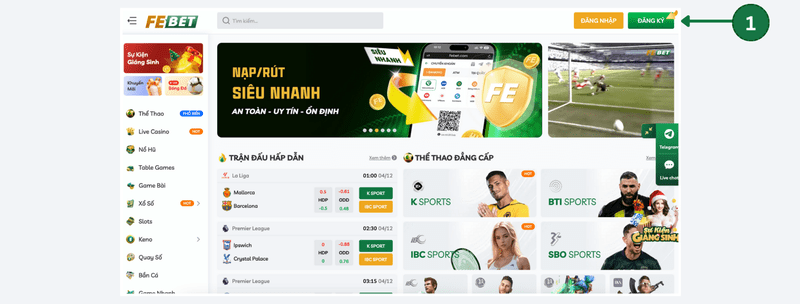

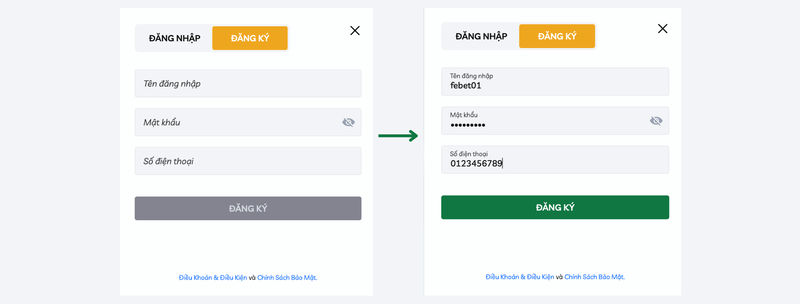

Hướng dẫn đăng ký tài khoản FEBET cực đơn giản

Để bắt đầu hành trình chinh phục FEBET, anh em chỉ cần làm theo các bước cơ bản sau:

Bước 1: Vào trang chủ FEBET và chọn “Đăng ký”.

Bước 2: Điền đầy đủ thông tin yêu cầu như tên đăng nhập, mật khẩu, số điện thoại, email…

Bước 3: Xác nhận và bắt đầu cuộc chơi thôi!

Chỉ với 3 bước đơn giản, anh em đã chính thức trở thành thành viên của đại gia đình FEBET

Và sẵn sàng khám phá kho game khổng lồ với vô vàn trò chơi gay cấn, kịch tính.

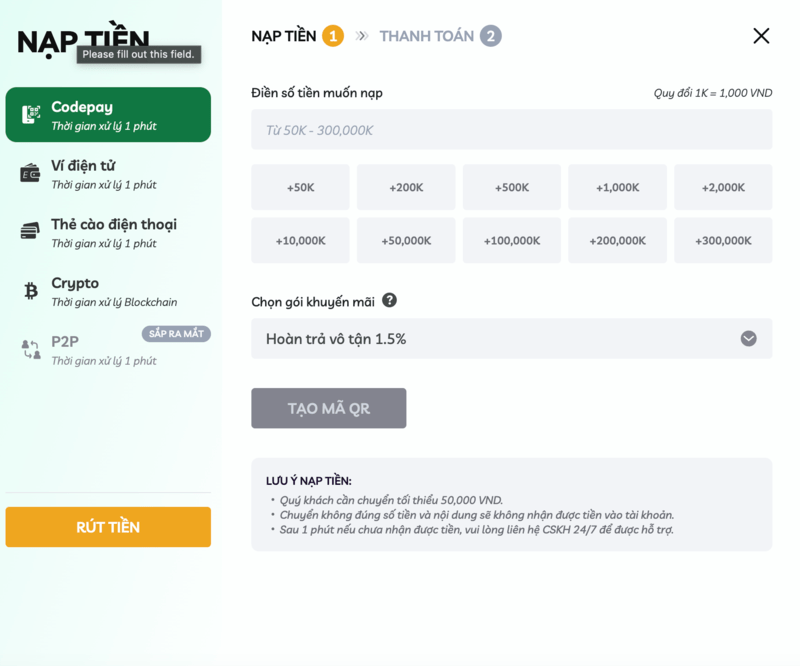

Hướng dẫn nạp tiền tại FEBET

Nạp tiền tại FEBET vô cùng nhanh gọn và dễ dàng. Anh em chỉ cần làm theo các bước sau:

- Bước 1: Đăng nhập tài khoản và chọn “Nạp tiền“.

- Bước 2: Chọn phương thức nạp tiền mong muốn (chuyển khoản, ví điện tử, thẻ cào…).

- Bước 3: Nhập chính xác số tiền cần nạp và thực hiện giao dịch theo hướng dẫn.

- Bước 4: Xác nhận và chờ hệ thống xử lý trong vài giây là tiền sẽ vào tài khoản ngay.

Nếu gặp bất cứ vấn đề gì, anh em cứ liên hệ bộ phận CSKH để được hỗ trợ nhiệt tình nhé.

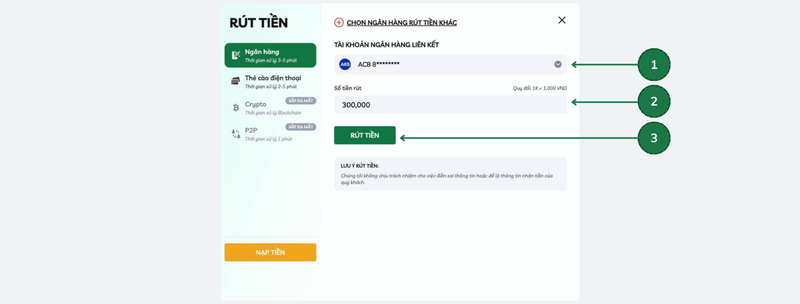

Hướng dẫn rút tiền từ FEBET

Tương tự như nạp tiền, rút tiền tại FEBET cũng diễn ra cực kỳ nhanh chóng và bảo mật. Anh em chỉ cần:

Bước 1: Đăng nhập và chọn “Rút tiền“.

Bước 2: Chọn phương thức rút tiền (chuyển khoản, ví điện tử), nhập số tiền muốn rút.

Bước 3: Xác nhận thông tin và chờ hệ thống xử lý trong 2-3 phút.

FEBET cam kết thực hiện lệnh rút tiền siêu tốc, giúp anh em nhanh chóng nhận được tiền thắng cược về tài khoản một cách an toàn nhất.

Kết luận

Trên đây là toàn bộ những thông tin cần biết về FEBET – Một trong những nhà cái cá cược trực tuyến uy tín và chất lượng nhất hiện nay.

Với những ưu điểm nổi bật như:

- Kho game khổng lồ, đa dạng thể loại

- Tỷ lệ thắng cao, trả thưởng hấp dẫn

- Hệ thống khuyến mãi “khủng” thường xuyên

- Nạp rút tiền nhanh chóng, bảo mật

- Đội ngũ nhân viên CSKH chuyên nghiệp, tận tâm

FEBET thực sự là một lựa chọn không thể bỏ qua đối với bất cứ anh em nào đam mê cá cược, đặc biệt là cá độ thể thao.

Nếu còn bất cứ thắc mắc gì, anh em đừng ngại liên hệ với bộ phận hỗ trợ của FEBET để được giải đáp tận tình nha.

Cuối cùng, chúc anh em có những giây phút giải trí thật sảng khoái và gặt hái được nhiều chiến thắng lớn tại FEBET.

Hãy trở thành một phần của đại gia đình FEBET ngay hôm nay để không bỏ lỡ bất cứ cơ hội “vàng” nào. Chúc anh em may mắn!